What is Powder Metallurgy?

Powder Metal Facility

Nowadays cost calculations are increasing the tendency towards powder metal technology, especially for sintered parts.

With this technology, parts can be produced with high precision, low waste rates and much shorter deadlines with high production speed and be more efficient than alternative production techniques. Most European companies are researching to reduce their costs by manufacturing the products with this technology.

You can find our product groups manufactured within our company with powder metal technology in the PRODUCTS section of our website. Please do not hesitate to contact us for the design, manufacture and delivery conditions of the custom goods you need in this regard.

Engineering

Our company provides engineering services in order to prevent possible pressing, processing and assembly errors in the products that come with customer demand.

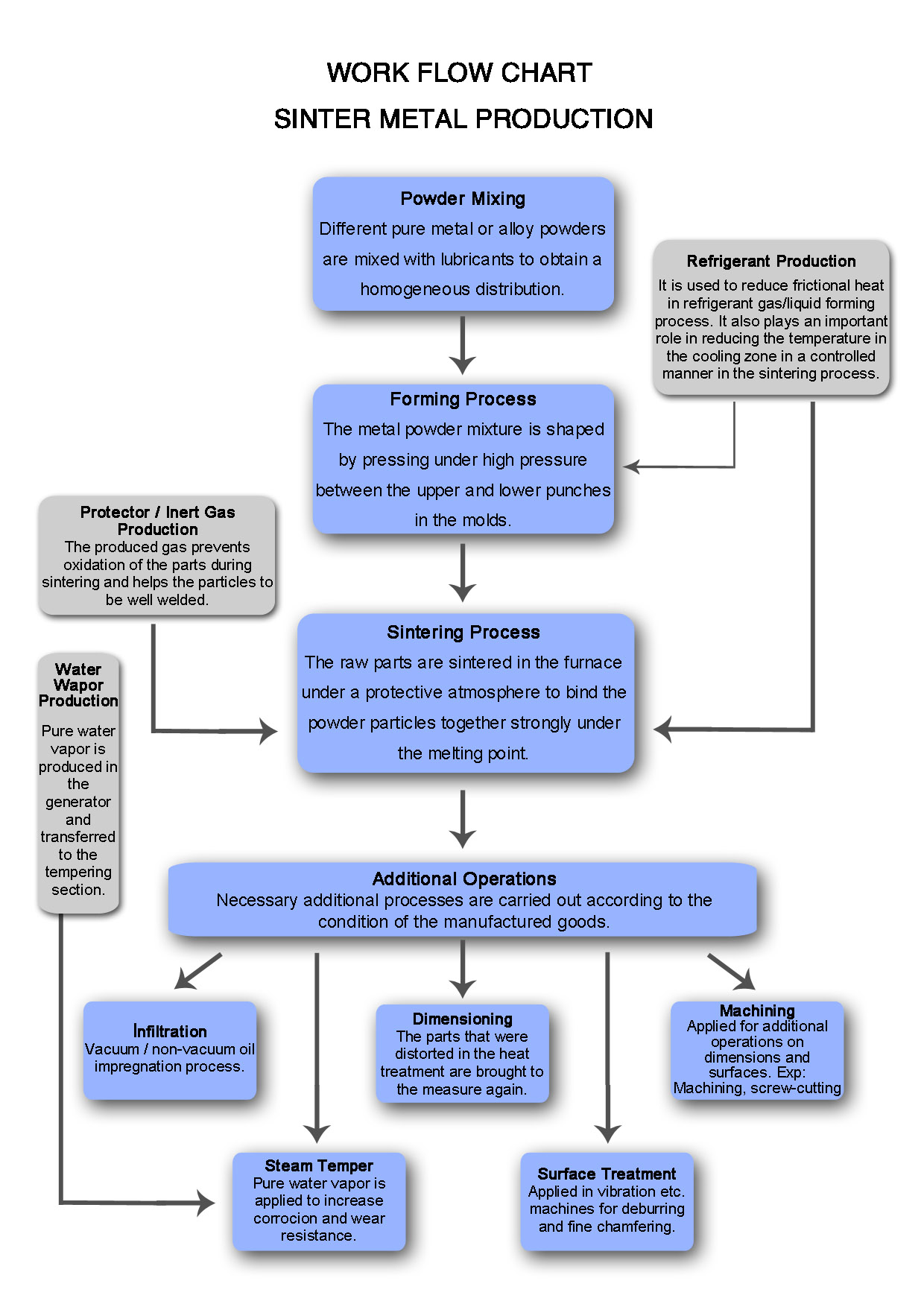

It is aimed to provide the highest quality continuously by providing engineering services with product structural design, pressing, sintering and calibration. In powder metallurgy processes, one of the most important steps that determines the quality of a good after raw material is mold design and manufacture.

R&D

Our company, which continues on its way with the philosophy of 'continuous development', not only designs the products to be produced, but also carries out improvement studies to increase the quality and safety of the products already produced, with our expert Engineer staff working in our R&D Department.

The importance of new ideas, R&D and innovation are always prioritized. The point that stands out here is not that a product is made for the first time in the creative solutions process, but that the innovation adds value to the user. As Sinterci, we continue to work with the aim of adding value with the projects we have developed. As Sinterci, in our R&D and innovation processes, we have taken our place in the market with a MORE economical, MORE efficient and MORE qualified goods unlike the sinter products that are already exist in the market.

Quality

Effective quality management systems are carried out in all processes in our institution. In the products and services we provide; A quality management system has been established that aims to keep customer satisfaction at the highest level, to manage customer feedback effectively, to eliminate processes that do not create value, to deliver on time with the effective use of resources, and to continuously improve.

It is aimed to provide our customers with zero defect products under the most economical conditions on time, to improve our quality continuously, and to develop by taking advantage of all the opportunities of advanced technology. It is one of the leading items of our quality policy to continuously improve the current situation in all matters, to make progress with our sub-industrialists and service providers in quality and logistics issues, to use all the possibilities of technology.